Biomass

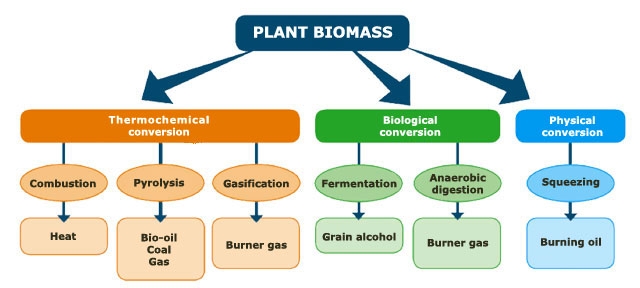

The vegetable material is produced as a result of the process of photosynthesis, which thanks to the energy of sun can transform simple minerals into complex organic molecules. The plant biomass absorbs CO2 (carbon dioxide) from the atmosphere during its growth, and it returns it during combustion. Therefore, the CO2 balance of these processes is zero, so it does not contribute to the greenhouse effect. Any material that has an organic matrix, like municipal waste, can be defined as biomass. For this reason we prefer to talk about “plant biomass”, limiting its origin to the plant world. The plant biomass energy is transformed by three processes, which can be grouped into three major groups:

- thermo-chemical

- biological

- physical

Different processes such as combustion, pyrolysis and gasification can generate the thermochemical conversion of the plant biomass energy. The biological conversion can be obtained by the alcoholic fermentation and digestion, while the physical conversion by squeezing.

COMBUSTION

Combustion is the more traditional process for the conversion of biomass. To be efficient, it requires a reduction of the water content of the biomass, obtained by drying the products to the sun. In Italy there are about 40 large systems generating biomasses electricity by combustion - generally turning residues from wood processing - for a total electrical power of about 330 MW. They are, indeed, co-generation plants: final energy is given by heat and electrical energy. Part of the heat produced is in fact used to produce steam, employed to power the turbines connected to electric generators. The part of the remaining heat can be used for industrial or residential users. The efficiency of these systems is of 20-25%, so it’s rather modest.

PYROLYSIS

Pyrolysis is a process for thermochemical decomposition of organic material, also called dry distillation, which is based on the transformation of biomass through heat, in strong oxygen deficiency. Pyrolysis can be applied to any organic material with low water content (<15%). The material is brought to temperatures between 200 and 700° C, and sometimes appropriate amount of oxygen can facilitate the inception of a partial combustion, which leads to a rising of temperature.

GASIFICATION

The biomass gasification process is a physical chemical process that occurs when a solid fuel (wood, biomass) is transformed in a gaseous fuel. The process consists in an incomplete oxidation of carbonaceous compounds brought to high temperature (about 1000 ° C), in an oxygen-deficient environment. The gas obtained, called syngas, can be used directly to power internal combustion engines, mainly employed for the production of electricity. The syngas is a mixture of nitrogen, methane, hydrogen, carbon monoxide and other gases. The conversion of plant biomass energy through biochemical processes can be split into two processes:

- alcoholic fermentation;

- anaerobic digestion.

FERMENTATION

Alcoholic Fermentation is a biochemical transformation process in which sugars are converted into ethyl alcohol. The production of ethanol from biomass with high sugar content has been fully tested: in Brazil the fermentation of sugar cane allows to obtain ethanol at a price that might be compared to the gasoline one. In Italy some sugar beet experiences have been made, but with poor results: processing costs were not convenient.

ANAEROBIC D

Anaerobic digestion is a process of conversion done by bacteria operating in a rich cellulose biomass; this process allows to obtain a biogas containing about 65% methane. This gas is used to fuel an internal combustion engine connected to an electric generator. The electricity produced is directly fed into the distribution network and sold at remunerative price (Green Certificate), as obtained from a renewable energy source. The digested residual component can be used as fertilizer. These kind of biomass power plants are very common in Northern Europe.

To better optimize the plants’ performance, it maybe convenient to get special device to use the produced heat, as for each kWh you get about 1 kWh of thermal energy.

SQUEEZING

The physical conversion is essentially a process of mechanical pressing of crops with high oil content (sunflower rapeseed, soybean). The end results are some edible squeezing oil and protein panels containing a higher percentage of oil (10% max), used by the animal feed industry.

The vegetable oil thus obtained, which is a mixture of methyl esters of fatty acids, can be used directly as fuel for diesel engines slightly modified, or be chemically treated to make it similar to diesel fuel (biodiesel).